This facility has a large machine shop comprising numerous Computer Numerical Controlled Vertical Boring Mills, capable of machining disc and ring components ranging from 100mm diameter up to 2.5m diameter to exacting tolerances for machining operations required before and after Ultrasonic testing.

The immersion Ultrasonic inspection facility is one of the largest Aerospace-qualified facilities in Europe. Forgings produced by Wyman-Gordon Livingston and Lincoln are machined and tested in our Plzen facility, but we also carry out this service for external customers.

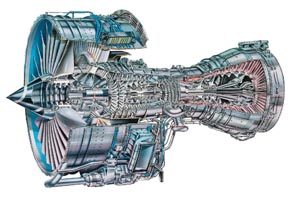

Products include:

- Fan Discs

- Rotor Discs

- Compressor Discs

- Turbine Discs & Shafts

- Spacer Rings

- Cover Plates

Titanium

- Ti 6-4

- Ti 6246

- Ti 6242

- Ti 843

- Ti 829

- Ti 685

- Ti 550

- Ti-17

Nickel

- Inco 718

- Inco 901

- Incoloy 909

- Waspaloy U720

Rolls Royce Engine

Equipment

- 26 CNC Machines

- 16 UltraSonic Tanks

- 3 Manual Machines

- LK CMM, LK/Metris CMM

- 2 PDQ Arms

- 2D Matrix part marking

- White Light Scanner

- Flow Detectors

Processes

- CNC Machining

(pre-ht, pre-sonic, post-sonic) - Mechanical Testing

(Incotest/Exova -2km) - Part Marking

(numeric code, 2D Matrix) - CMM Inspection

- 3D Pro E software

(docu., process optimization) - Marking Off

(cold forge inpsection) - Dimensional Inspection

- UltraSonic Inspection

Inspection & Non-Destructive Testing

- 100% Quality Inspection

- Ultrasonic Flaw Detection

- Florescent Dye Penetrant

- Magnetic Particle Inspection

Quality Approvals

- ISO9001:2000

- AS9100:2004